High pressure pump cement mill YouTube

Sep 02, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Sep 02, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Alarm 179 LOW GEARBOX OIL PRESSURE: The oil level is low. Fix the leaks and refill with oil. After adding oil power cycle the machine to tirgger oil level measurment. Overfilling the gearbox with oil will cause it to leak. There is a clog in the oilpump inlet screen. Clean the oilpump inlet screen.

A new method is proposed to estimate pumping pressure based on concrete composition without experimental measurements. Previous studies show that the pumping pressure depends on the interface friction between concrete and the wall of the pumping pipes. This friction is determined by the thickness and the rheology of the boundary layer formed at the interface.

Pumps often have replaceable wear plates on one or both sides of the impeller. Mining, minerals processing, transportation of slurries for processing, and dredging. Also pumps used in slurry applications in coal fired power plants, steel mills, cement mills, etc. Very abrasive liquids of all types.

Portland Cement— Portland cement shall conform to the requirements of Material Specification 531, Portland Cement, for the specified type. If the cement contains lumps or foreign material that would clog the grouting equipment or interfere with grout injection, it shall be screened through a 100mesh screen.

Jan 13, 2014· Mill Lubrication System 1. OBJECTIVES: To identify the definition and importance of a hydraulic lubrication system. To be familiarized with the lubricant and equipment used in the system. To understand the process and various design of Mill lubrication system. To identify some problems encountered by the system, and formulate some recommendation to help fix the problems.

Over time water and ice can damage the concrete inside the crack and work around the grout. This method is especially unreliable with hairline cracks and where water pressure and water flow is present. Low pressure injection also works better with rigid grout that exerts more of its own force as it cures and expands into the crack.

Oct 13, 2010· ''Head'' and ''pressure'' in pumps ... AL, steel mill. When one of our water pumps failed in the cooling ponds one day, my boss gave me a requisition order and the keys to a company truck. He told me to go into the city and purchase another pump at the industrial supply house.

SLURRY PUMPING MANUAL iv–1 Symbols used The terms slurry and mixture in this Manual are used interchangeably to describe a mix of any loose solids, made up in any proportions and combinations of any particle sizes and any conveying subscript w refers to densities and specific gravities of liquids – mostly, but not exclusively, water.

Oct 10, 2015· Deep Cement Mixing Trial in Mekong Delta. 8 KNOTS You Need to Know How to tie knots that you will actually use. Duration: 15:14.

1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill ... • Lowvibration mill running, even in partial load ranges down ... ment was first realised in 1970 for grinding mills in the cement industry.

under conditions of low pressure. There is a high point in our system where we know the pressure will be low but exactly how low? The techniques in this article will show you how to do this calculation for any point in the system. Calculating the pump total head sometimes involves calculating the pressure in different parts of the system.

Higher cement content mixes are generally easier to pump. The difference between a typical 3000 PSI mix and a typical 4000 PSI mix is that there is approximately 100 pounds more of cementious material and approximately 85 pounds less sand in the 4000 pound mix. Cement is the sliding agent in concrete; while sand is abrasive

Grout pumps can be used to fill small voids and door jams and they are available in either manual, electric, gas, hydraulic and air powered. Concrete pumps are strong enough to lift up many stories and even lift slabs of concrete. It''s worth mentioning that certain model concrete pumps .

Dec 16, 2016· Lowvolume, highpressure pump: The ProCretor is a lowvolume, highpressure concrete pump/mixer designed for a number of applications, including shotcreting, pressure grouting, refractory work ...

All Reinert STube Concrete Pumps include the Hinge Valve as standard equipment. Other standard features include a variable volume piston pump and a convenient remote control cable. Our hoppers are designed with straight walls and minimum corners to allow for easy cleanup and little buildup. An optional radio remote control is available.

The Protected Gauge Assembly is complete as shown, including highpressure camlock fittings for gauges up to 1500 psi and hammer unions for gauges over 1500 psi. Available for all ChemGrout equipment with working pressure ranges of 015 psi thru 02,000 psi.

Mar 03, 2010· Back in November 2007 a new world record height of 601 m for pumping concrete was set by a 14000 SHP D super high pressure concrete pump being operated by Unimix on the Burj Dubai Tower in Dubai. However, this record was not to stand for very long, as it was broken in April 2008 when the same company using the same pump achieved a height of 606 m.

Welcome to ChemGrout For more than 55 years ChemGrout has manufactured the world''s largest selection of grouting equipment. Based in LaGrange Park, lllinois, ChemGrout offers both colloidal and paddle type grout mixers, as well as a variety of grout pumps, including piston, plunger and progressing cavity. The concepts of mixerpump balance, userfriendly operation and ease of maintenance are ...

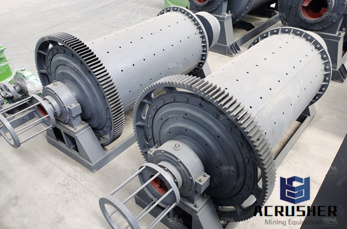

The ball mill''s low pressure oil system pumps oil from the reservoir through a filter assembly to clean the oil before the flow is sent to the trunnion bearings. During startup, the oil is also pumped to the high pressure pump. Dual cartridge filters, connected in parallel, continually clean the oil.

Low pressure injection crack repair begins with the surface sealing of the crack and the placement of the surface ports along the crack opening. The best material for this is epoxy pastes. Epoxies bond very effectively on to clean, dry roughened concrete surfaces. This is accomplished by scraping the crack area with a wire brush.

GCP20HH hose pump for pumping concrete GH100915B Super high pressure bentonite hose pump GCP40HE Hose Type Concrete Pump Squeeze Hose Grouting Pump for TBM Customize Hose Pump for Grouting Cement GCP15HE/D Hose Type Concrete Pump GHB Hose Pump for Filter Press Machine GH89610C Squeeze Hose Pump for TBM Industrial Peristaltic Pump ...

Mar 26, 2007· Low pressure version fills block and door frames. Ideal for filling concrete block and hollow metal door frames, the GP8A airpowered pump moves most cementitious grout anywhere that high pressure is not required. It pumps up to 9 gpm and uses less than 6 cfm of air. The pump weighs 38 lb and includes a start/stop switch and adjustable speed ...

Pumping concrete: line pressure and equipment choice How to figure the best combination for smooth, efficient operation The first step in planning a concrete pumping sys tem is to determine the capacity and pre s s u r e re

WhatsApp)

WhatsApp)