LOESCHE technology for cement plant in Angola

Jun 09, 2016· designed to have a capacity of 150 t/h cement each. Furthermore LOESCHE''s coal mill of the type LM DC completes the order of the famous and reliable LOESCHE vertical roller mills.

WhatsApp)

WhatsApp)

Jun 09, 2016· designed to have a capacity of 150 t/h cement each. Furthermore LOESCHE''s coal mill of the type LM DC completes the order of the famous and reliable LOESCHE vertical roller mills.

Coal mill capacity calculation. Ball mill capacity how to calculate Coal Surface Mining western posts related to 10 tonne per Get Price Towards optimising ballmilling capacity Effect of lifter design The effect of linerlifter profile on kinetics of batch grinding and the milling capacity in general was assessed using monosize quartz material of 30 ×

calculation of false air entry in coal mill. Sir, We are supplying hot air from cooler to coal want to check the false air entry into the mill. Is there any method to do that... Hare Ram . Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply.

Canadian cement clinker production capacity is about million tonnes per year. In 1998, clinker production ... Figure 4 helps cement plants compare their own energy use to that ... damper in its coal mill with a variable inlet vane damper. The

grindingonly plants to seven. cement manufacturing is primarily a fossil fuel fired industry with % of all plants using coal, petroleum coke, or some combination of the two as primary kiln fuel. Nine plants reported using alternative fuels as primary kiln feed. There were 64 plants, or roughly 67% of total industry capacity,

Sep 07, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

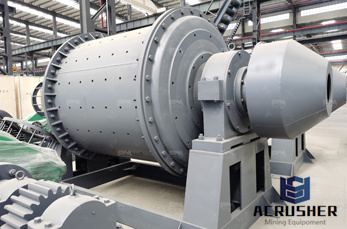

Cement ball mill, cement clinker grinding mill for cement plant. Cement ball mill is used to grind crushed cement clinker, gypsum rock . coal etc. for cement mill in cement production line is of low cost, high capacity etc.

The emission limit values shall be set by national authorities based on "best available techniques" for the relevant industrial sector. The aim of this Document is to provide background information on the cement industry and cement manufacturing technology, and to determine "best available techniques" for the installations for production of cement.

vi Normalisation Methodology for Cement Sector Coal Quality in CPP 43 Power Mix 44 Product Mix 48 Different cases in Cement Plants of Product Mix and use of Normalisation 52 Normalisation Others (REC Mechanism) 52 Environmental Concern 52

Installed Capacity (Cement) 3 MTPA Captive Power Plant (CPP) 27MW ... Coal Mill Pfeiffer 40TPHHG, 25Petcoke 24 TPH 4% Cement mill Pfeiffer 300TPH 350 TPH 17%. ... Cement Mill Productivity increase by 3% by modification of Classifier Annular Gap Oct''18

Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. These mills are usually found in utility plants. Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and table.

coal crusher standard calculation association roter . coal crusher standard calculation association coal pdf. difference between crushing coal crusher and pulverizer youtube. tube mill capacity calculation for coal coal pulverising in boilers find science · grind. 50 hgi normally is taken for calculating the base capacity of the mill.

Bhutan: A broken gearbox at a coal mill at the Penden Cement Authority plant in Gomtu has reduced its production. The plant has had intermittent mechanical issues with the gearbox in one of its two coal grinding mills since April 2017 leading to a breakdown in May 2017, according to .

Mar 01, 2016· China''s mammoth cement sector includes at least 803 cement plants and /yr of integrated cement production capacity, according to the Global Cement Directory 2016. This constitutes around % of global integrated cement capacity. China consumes correspondingly massive amounts of coal, the primary fuel source of Chinese cement plants.

how to calculate coal mill capacity in France – Crusher South Africa. how to calculate coal mill capacity – Grinding Mill China Posted at: July 27, 2012. .Calculation of Coal Bunker Size for Thermal Power Plant . »More detailed

The mill has a capacity of . ATOX coal mill FL. This can be achieved at a cement plant by using exit gases from the kiln sumption of an ATOX coal mill based the capacity, including residual . Coal mill pulverizer used in cement . Coal mill is the machine used in cement mill manufacturer SBM supplies coal mill, coal pulverizer for ...

How to calculate capacity of coal bunker stoere . how to calculate capacity of coal bunker Calculation of Coal Bunker Size bulk Diese Seite bersetzen Calculation of Coal Bunker Size for Thermal Power Plant Dear Sir Madam, Can anyone pr Tube Mill Capacity Calculation For Coal, raymond mill capacity coal crusher coal crushing plant with capacity find the right and the top

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Jan 22, 2016· Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along with some dust particles. Coal Mill Fans. In cement industry coal mill fans are used to supply required air for burning coal and remove the exhaust gases produced after burning.

coal crusher capacity calculation . design and analysis of a horizontal shaft impact crusher ethesis. ... how to calculate coal mill capacity in France ... Know More how the coal crusher capacity decided

3. running stably and continually, the production capacity is great. Compared with ball mills with the same specification, the yield of coal mill increases drastically, and the finished product is fine, achieving the highyield and superfine goal. It provides a new kind of grinding equipment to produce highquality pulverized coal.

Coal Crushing Plant with Capacity 50 . manual conveyor belt cema pdf . ball mill Barite crushing plant Barytes Crusher Cement Mill coal crusher coal crushing . large capacity coal crushers Gulin provide the large capacity coal crushers solution case for you. . two stage gearbox for a coal mill grinder moisture meter for crushed coal ...

Modern Processing Techniques to minimize cost in Cement Industry Batra, Mittal, Kamal Kumar P N Chhangani ... meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This mill ... several cement plants .

Grinding mill tph mill tph bbnonnapinaeu new cement grinding mill capacity up to 150 largest cement mill tph allanswersin grinding trends in the cement industrylargest cement mill tph,wide percentage of new ball mills for raw material and coal grinding is, clinkercement grinding is the biggest market, 420 tph.

WhatsApp)

WhatsApp)