Used Processplants For Sale King

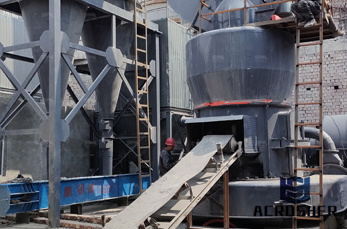

Buy used Processplants from King Industries. We can help guide you to the best solution for your equipment needs. Used Mining Processing Equipment Grinding Mills, Crushers Process Plants

WhatsApp)

WhatsApp)

Buy used Processplants from King Industries. We can help guide you to the best solution for your equipment needs. Used Mining Processing Equipment Grinding Mills, Crushers Process Plants

This chapter provides an overview of some of the key drivers for gold process plant design on an area basis, from comminution to cyanide detoxification. Also covered are special issues for large facilities, constructability aspects, and some of the pitfalls encountered in feasibility study plant design.

Metallurgical Plant Design and Operating Strategies Conference – Perth, March 2006 Abols, J., Gannon, S., Gray,, Hughes, T. Commissioning and Operating Experience with Gekko''s Gold Ore Treatment Plants 2 flotation, and intensive cyanidation, using the Gekko InLine Leach Reactor (ILR), very high overall recoveries can be achieved.

commercially viable gold and silver recovery mining processes. We can suggest the optimal process and equipment for virtually any ore. Although we are not a testing laboratory, we can design and coordinate your testing program. If we don''t have the answers, our network of .

The Mining Process Waihi Gold. A slurry of ground ore water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver

information on cyanide leaching of gold leach plants > Cyanide Leaching Of Gold ... a "heap". And while the pile of ore is called a heap, it is not a haphazard pile of rocks. Much thought and design goes into the making of a heap leach, to derive the best, most economical solution for recovering the gold from the ore. ... One is the Merrill ...

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

Jan 05, 2018· Cyanidation machine supply please contact email: rocky

Gold extraction plant design gwp wash plant for sale gold gold extraction process plant design request a quotation mobile gold extraction plant a good design of gold ore crushing plant can click to chat now msi mining msi mining equipme. MOVE. Mine plant design and its process. Cip plant, cip plant suppliers and manufacturers at mine plant ...

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

gold from loaded carbon were developed, that the process came into widespread use for gold recovery from ore. These procedures allowed the carbon to be recycled for further gold recovery. Today, many options are available to the recovery plant designer and operator for the stripping of gold from carbon.

Carbon in pulp (CIP) is an extraction technique for recovery of gold which has been liberated into a cyanide solution as part of the gold cyanidation process. Introduced in the early 1980s, Carbon in Pulp is regarded as a simple and cheap process.

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

levels requires a combination of design flexibility and horsepower that only Flowserve offers. Design options include submersible motor pumps, axially split single and multistage pumps and reciprocating plunger pumps. Process Water Mining processes require steady and reliable delivery of fresh and reclaimed water for processing, heating,

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Extract gold from its ore has a long history in our human history, which can be dating back to sometime around BC. And we may still remember some notable Gold Rushes in recent centuries. In the modern mining industry, washing and extracting gold is not a oneoff process. It needs some significant washing process . Read more

Oct 20, 2014· Leaching gold with a cyanide solution remains the most widely used hydrometallurgical process for the extraction of gold from ores and concentrates. Despite the difficulties and hazards of working with cyanide, no other process has yet been proven to be an economic viable alternative.

A sodium cyanide process is used to extract the gold from the ore, and variousother processing techniques are used to produce 99. 9% pure gold bullion from the ore. The results of the feasibility study show that the ore can be processed by agitationleaching, which is preferred over heap leaching due to the low recovery associated withthe heap leaching technology. The .

The process design of gold leaching and carboninpulp circuits 14 JANUARY/FEBRUARY 1999 The Journal of The South African Institute of Mining and Metallurgy Figure 2—The CarbonInPulp (CIP) process Figure 1—ComputerAided Process Engineering (Cape)

The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon. CIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tanks.

Innovative Gold Plant Design for Better Returns . Gekko also offer a readymade modular plant known as the Gravity Flotation Intensive Leach (GFIL) system. GFIL is a complete offtheshelf gold processing modular plant designed to advance traditional whole ore cyanidation. It''s ideal for mines and ores with: Restricted cyanide use permissions

May 26, 2013· Mineral Processing Plant Design, Practice, and Control (2 Volume Set) [Andrew L. Mular, Derek J. Barratt, Doug N. Halbe] on *FREE* shipping on qualifying offers. This 2 volume set is an uptodate reference based on .

Aug 01, 2017· It was found that the suggestions of the CBR system provided useful information and direction for further process design and performed well compared to the interviewed human experts, thus confirming that the system is of practical relevance to the process engineer designing an industrial gold processing plant.

The 25million metallurgical process plant processes million tonnes of goldbearing ore per annum. It employs innovative concepts coupled with proven design technology. Fluor performed detailed design of the processes, structures, and mechanical and electrical works, as well as construction.

WhatsApp)

WhatsApp)