New dry iron ore processing technology ... Australian Mining

May 26, 2016· The method does not use water to process iron ore, instead it transforms mining tailings – with low iron content and no commercial value – into high iron .

WhatsApp)

WhatsApp)

May 26, 2016· The method does not use water to process iron ore, instead it transforms mining tailings – with low iron content and no commercial value – into high iron .

Integrated iron ore mines, rail and port operations in the Pilbara region of Western Australia Explore our global locations Western Australia Iron Ore (WAIO) is an integrated system of four processing hubs and five mines connected by more than 1,000 kilometres of rail infrastructure and port facilities in the Pilbara region of northern Western ...

Jun 05, 2019· In a text message, Guinean Mining Minister Abdoulaye Mgassouba said the country''s aim was that "all the projects to exploit iron ore are developed in a way to give Guinea a presence on the ...

To efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory. Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron ore (DRI) needs to be applied to stay competitive and ...

Mining Mining Underground mining: When any ore body lies a considerable distance below the surface, the amount of waste that has to be removed in order to uncover the ore through surface mining becomes prohibitive, and underground techniques must be considered. Counting against underground mining are the costs, which, for each ton of material mined, are much higher underground than on the ...

Engenium, a project delivery and engineering consultant to Australia''s mining sector, was tasked with providing a feasibility study to design new magnetic separation technology. The technology will increase ironore production at an existing plant in the Pilbara region of Western Australia.

Iron Ore Mining in Australia industry trends () Iron Ore Mining in Australia industry outlook () poll Average industry growth : lock Purchase this report or a membership to unlock the average company profit margin for this industry.

Refined Iron | The Tekkit Classic Wiki | Fandom powered by ...

Jul 14, 2020· The iron ore boom powering the profits of the world''s biggest mining companies is showing no sign of fading thanks to Chinese steel demand. ... iron ore has been aided by continued production ...

Mining Iron Ore Iron ore is an important commodity currently in high demand due to population and infrastructure growth in developing countries. Whether you are involved in iron ore exploration, processing or trade, SGS provides a comprehensive range of services to support these activities.

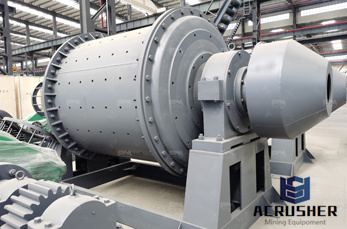

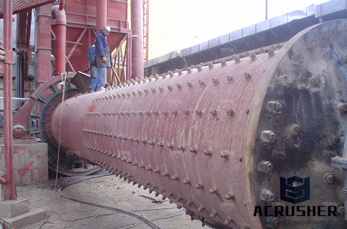

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill, Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer.

Aug 24, 2016· INTRODUCTION TO MATERIALS – This is the first post on materials. Iron ore and steel production. The 6minute video explains the mining and processing of iron...

Iron ore is the source of primary iron for the world''s iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries.

Iron ore is the key component in steel, the most widely used of all metals. In South Africa our iron ore operations are made up of a % shareholding in Kumba Iron Ore Limited (Kumba), a leading supplier of seaborne iron ore. Kumba is listed on the Johannesburg Stock Exchange and operates three mines.

shipping. The process of mining low grade iron ore, or taconite, requires massive resources. Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required. The equipment used includes diamond bit rotary drills, hydraulic shovels and loaders, water wagons, production trucks and heavyduty conveyors.

Metallurgical ContentThe Iron Ore Process FlowsheetCRUSHING AND GRINDINGHYDROCLASSIFICATION AND MAGNETIC FINISHINGCONDITIONING AND FLOTATIONSILICA FLOTATION REAGENTSTHICKENING AND FILTERINGADVANTAGES OF FLOTATION Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron .

In addition to mined iron ore, other sources of iron, such as flue dust collected from blast furnaces, or the dust produced at mine sites, is also frequently pelletized so it can be utilized, as opposed to disposed of. The Pelletizing Process. The production of iron ore pellets from fines to finished product can differ based on a variety of ...

Jun 26, 2020· SP Global Platts labelled iron ore as "the standout commodity", with demand for the commodity proving to be "extremely resilient" this year.

Production guidance for the 2020 financial year remains unchanged for petroleum, iron ore and metallurgical coal. The miner''s iron ore output came in at 68 million tonnes for the quarter ended ...

The world will need iron ore for as long as the world needs steel. In 2019, we produced 270 million tonnes of iron ore. That''s enough to make the steel for more than 3,100 Sydney Harbour Bridges. We''re building a new iron ore mine in Western Australia. When completed, South Flank will produce highquality iron ore for around 25 years.

Iron ore is an ore that can be obtained through mining iron rocks, requiring level 10 Mining, in various places around RuneScape.. Iron is required to craft iron and steel bars, and is also a tertiary ingredient for creating granite crab players increase their Mining level and use higher tier pickaxes, they are able to mine iron at quicker rates.

Dec 31, 2018· Australia''s total production of iron ore for 2018 was 899 Mt (Table 3), with Western Australia producing 891 Mt or 99% of overall production. South Australia and Tasmania produced the remaining 1% of iron ore in 2018 with 6 Mt and 3 Mt, respectively. Rio Tinto Ltd reported 2% production growth at its Pilbara mines with output of Mt in ...

Jan 05, 2018· Picture of iron ore consumption by country is somewhat different compared to the top iron ore producing countries. Iron ore in these countries is mostly used for steel production, and those top steelconsuming countries (based on 2013 figures) are China, Japan, USA, India, Russia, South Korea, Germany, Turkey in this order.

Jan 02, 2012· With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century''s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

WhatsApp)

WhatsApp)