manufacturing process of silica sand YouTube

Oct 01, 2012· Fascinating Silicone™ Manufacturing Silicone from Sand: process of making silica sand from quartz:

WhatsApp)

WhatsApp)

Oct 01, 2012· Fascinating Silicone™ Manufacturing Silicone from Sand: process of making silica sand from quartz:

Silica is one of the most common hazards on a worksite, particularly in the construction, oil and gas, manufacturing, and agriculture industries. Silica dust can cause silicosis, a serious and irreversible lung disease. It can also cause lung cancer. Cutting, breaking, crushing, drilling, grinding, or blasting concrete or stone releases the dust.

OSHA''s Silica Exposure Enforcement: Are You Ready? Don Sears ... Safety managers in manufacturing can prepare for the 2018 silica exposure enforcement date by better understanding what is happening in construction. ... "Anybody in general industry that does abrasive blasting that may either be using silica sand or may be blasting on ...

Whenever materials containing crystalline silica — masonry, brick, stone, concrete, glass — are sawn, drilled, chipped or crushed, silica dust is created and released. Silica sand is especially problematic because it is grainy and dusty, even in its natural state. Most particles are 100 times smaller than sand found on beaches. Silica Exposure

Dave Anderson, Technical Director of the Risk Control Industrial Hygiene Specialist Group for Travelers. Earlier this summer, new standards for respirable silica dust were put into effect by the Occupational Health and Safety Administration (OSHA) Crystalline silica, a carcinogen found in sand, stone and artificial stone, can cause silicosis, a chronic disease that involves scarring .

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula Si O 2, most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of is one of the most complex and most abundant families of materials, existing as a compound of several minerals and as synthetic product.

Silica Sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules. Commercial Silica Sand is widely used as a proppant by companies involved in oil and natural gas recovery in conventional and unconventional resource plays. The resource is also used in industrial processing to make everyday

Silica is a global industrial minerals and logistics leader, with core competencies in mining, processing, logistics and material science that enable us to produce and cost effectively deliver over 1,500 diversified products to customers across our end markets.

Crystalline silica is a common mineral found in the earth''s crust. Materials like sand, stone, concrete, and mortar contain crystalline silica. It is also used to make products such as glass, pottery, ceramics, bricks, and artificial stone.

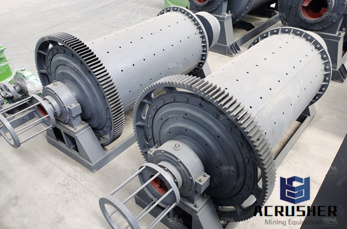

The main purpose of silica sand is the product expansion to make glass, casting, ceramics and refractory materials, smelting and other relevant. However, processing, processing for silica sand, according to different purposes appeared many for silica sand mining equipment, which is widely is silica sand crushing machine, milling machine and so on.

Sep 13, 2016· Occupational exposure to airborne silica dust occurs in operations involving cutting, sawing, drilling, and crushing of concrete, brick, block, and other stone products, and in operations using sand products, such as in glass manufacturing, foundries, and sand blasting.

Apr 23, 2013· Silica sand and glass industry 1. Topic 4: GLASS Hassan Z. Harraz hharraz2006 2013 2014 ... because of the need for a high degree of chemical purity. The essential requirements for silica sand for glass manufacture are that it must be even grain size more than 90% of grains must lie in the range 125500µm, and its chemical ...

G3 is the only supplier of feldspathic silica sand to glass container manufacturers in Northern and Central California. The Highest Quality Control Standards. G3 silica sand meets the exacting quality control standards required for glass manufacturing. Product specifications include: A silica (SiO2) content greater than 90%

We, Mars Enterprises offerings moral values, quality standards and excellent financial stability as the Manufacturer and Supplier of Quality Silica Sand, Silica Beads etc in Gol Residency, Nana Mava Main Road, Behind Vrundavan, Rajkot, Gujarat, India

Crystalline silica is found in sand, stone, concrete and mortar. When workers cut, crush, drill, polish, saw or grind products containing silica, dust particles are generated that are small enough to lodge deep in the lungs and cause illness or disease including silicosis.

Apr 01, 2016· OSHA''s Silica Requirements now "Crystal" Clear for the Construction Industry ... a similar article has been published on silica for the manufacturing industry. Silica is found in the most common building materials on the planet including sand, mortar, concrete, asphalt, drywall, drywall compound, bricks, blocks, stone, tile, and many more ...

Occupational exposure to airborne silica dust occurs in operations involving cutting, sawing, drilling, and crushing of concrete, brick, block, and other stone products, and in operations using sand products, such as in glass manufacturing, foundries, and sand blasting.

Oct 01, 2012· silica sand manufacturing process: ... Firstly,quartz stone is ... silica sand making glass equipment; ... VSI crusher is the special quartz crushing machine used in sand making process ...

Workers involved in manufacturing, finishing, and installing natural and manufactured stone countertops . are at risk for significant crystalline silica exposure. Crystalline silica commonly occurs in nature as the mineral quartz, and is found in granite, sandstone, quartzite, various other rocks, and sand. Workers who

Crystalline silica is a common mineral found in the earth''s crust. Concrete, mortar, sand, and stone are some materials that contain crystalline silica. It is also used to make . products, such as bricks, ceramics, glass, pottery, and artificial stone. 2

New OSHA Silica Testing Requirement in Effect. OSHA has issued two standards ("rules") to minimize exposure to respirable crystalline silica. One rule applies to construction trades, and the other for general industry and maritime workplaces. This blog focuses on the new OSHA Silica Testing requirements for the construction industry.

Apr 01, 2016· New Silica Rule Has Implications for SDS Authoring, Workplace Signage Apr 1, 2016 As industry experts begin to analyze the new 1700+ page respirable crystalline silica PEL rule released by OSHA late last week, it''s becoming clear that the expansive nature of the rule will result in new responsibilities for workplaces.

What are the Damaging Effects of Silica Dust? Silica dust is an extremely common, and potentially hazardous, mineral compound found throughout numerous industries and applications across the globe. It exists in nature primarily as quartz, although in many areas it is a major component in sand.

Silica sand is also normally required to be wellsorted, to have grains of an approximately uniform size. Most sources of sand used by the construction industry do not satisfy these requirements and are not, therefore, suitable for glassmaking. Industrial uses of silica sand depend on its purity and physical characteristics. Some of the

WhatsApp)

WhatsApp)