precast concrete fencing panels production DIY YouTube

May 25, 2017· here show the precast concrete fencing panels making easy diy.

WhatsApp)

WhatsApp)

May 25, 2017· here show the precast concrete fencing panels making easy diy.

Jul 31, 2013· Charge is introduced into a rotary rotary kiln consists of a steel cylinder about 150meters long and 4meter diameter and rotates 30 to 60 turns per one end of the cylinder a screw ...

Global steel production is dependent on coal. Over 71% of the steel produced today uses coal. Metallurgical coal – or coking coal – is a vital ingredient in the steel making process. World crude steel production was billion tonnes in 2017.

The product is an intimate mixture of compounds collectively called clinker. This clinker is finely ground into the powder form. The raw materials used to make cement are compounds containing some of the earth''s most abundant elements, such as calcium, silicon, aluminum, oxygen, and iron. Water is a key reactant in cement hydration.

Mar 28, 2017· Primarily for cement grinding plants in India, coal (generally of bituminous grade) is used in the slagdryer. The wet slag arrives at the stack on wagons from some nearby steel plant, or it may be brought via a trolleysystem (primitive mode). Bu...

Making steel without coal. This is a holy grail for emissions chasers and there has been considerable international research on ways of reducing or eliminating CO 2 emissions. Recycling steel. Around 500 million tonnes of steel is recycled every year from scrap, or 31% of total global steel production.

Today, concrete block manufacturing is a highly automated process that can produce up to 2,000 blocks per hour. Raw Materials The concrete commonly used to make concrete blocks is a mixture of powdered portland cement, water, sand, and gravel.

The Romans mixed natural pozzolans with lime to make the first hydraulic cement. Fly ash. Dust collected in the stacks of coalfired power plants, used as a supple mentary cementitious material in concrete and mortar. ... Form release compound. A substance applied to concrete form work to prevent concrete from adhering. Precast concrete.

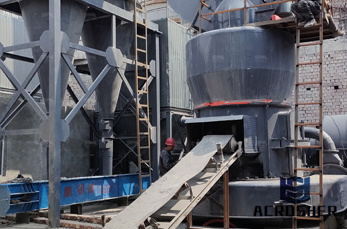

Vertical compound crusher (compound crusher), is one of the common equipment in crushing plant and sand making plant. it can be widely used in crushing raw materials, clinker of cement plant, also available in medium hardness materials fine crushing of dolomite, leadzinc mine, serpentine, blast furnace slag, coal gangue, phosphate rock and so on.

Fly ash or flue ash, also known as pulverised fuel ash in the United Kingdom, is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue that falls to the bottom of the boiler''s combustion chamber (commonly called a firebox) is called bottom ash.

Asphalt paving material is a dull black mixture of asphalt cement, sand, and crushed rock. After being heated, it is dumped out steaming hot onto the roadbed, raked level, and then compacted by a heavy steamroller. Asphalt is also used for expansion joints and patches on concrete roads.

This grey pebblelike material comprises special compounds that give cement its binding properties. Clinker is mixed with gypsum and ground to a fine powder to make cement. Coal is used as an energy source in cement production. Large amounts of energy are required to produce cement.

When mixed with lime and water, fly ash forms a compound similar to Portland cement. This makes fly ash suitable as a prime material in blended cement, mosaic tiles, and hollow blocks, among other building materials. When used in concrete mixes, fly ash improves the strength and segregation of the concrete and makes it easier to pump.

ordinary temperatures to form compounds having cementitious properties. Pozzolans that are commonly used in concrete include fly ... it is possible to make concrete with moderate strength using the fly ash as the sole cementing material (Cross 2005). ... coal source or as Class F .

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting cement will have the desired chemical composition. These ingredients are ground into small particles to make them more reactive, blended together, and then the resulting raw mix is fed ...

Cement is seldom used on its own, but rather to bind sand and gravel together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Cement is the most widely used material in existence and is only behind water as the planet''s mostconsumed resource.

Oct 05, 2019· The primary difference between concrete and cement is that concrete is a composite material made of water, aggregate, and cement. Cement is a very fine powder made of limestone and other minerals, which absorbs water and acts as a binder to hold the concrete cement is a construction material in its own right, concrete cannot be made without cement.

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as is a complex process that is best understood by first understanding the chemical composition of cement.

Coal—A Complex Natural Resource. An overview of of factors affecting coal quality and use in the United States . By Stanley P. Schweinfurth. INTRODUCTION. Coal is abundant in the, is relatively inexpensive, and is an excellent source of energy and byproduct raw materials.

Energy Consumption Benchmark Guide: Cement Clinker Production Industry Background Cement is produced at 17 locations across Canada. The industry is

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

To conclude this video, let me summary the essentials that you have to remember: Coal tar is made from coal, but it is hazardous and it is forbidden in more and more countries. Cement is made from limestone, it is used to build rigid structures and is bitumen''s main competitor.

Variances in the chemical composition of fly ash from different sources compounds the problem by making it difficult to assure the proper strength of the final concrete products. Traditional masonry takes significant volumes of energy to produce, concrete and brick making are some of the biggest sources of greenhouse gasses.

Clinker: reactions in the kiln. The milled and blended raw materials go to a silo and then to the kiln. Reactions which take place as the feed passes through the kiln are reviewed below. They can be considered under three broad headings: Decomposition of raw materials .

WhatsApp)

WhatsApp)