Mathematical model of a ball mill | SpringerLink

Civil Engineering Institute, Kharkov. Translated from FizikoTekhnicheskie Problemy Razrabotki Poleznykh Iskopaemyh, No. 4, pp. 87–90, July–August, 1980.

WhatsApp)

WhatsApp)

Civil Engineering Institute, Kharkov. Translated from FizikoTekhnicheskie Problemy Razrabotki Poleznykh Iskopaemyh, No. 4, pp. 87–90, July–August, 1980.

As a result, a new mathematical model for determining the wheel location and a software program for simulating the generation of the rake face of a ball end mill are proposed. In addition, methods for grinding the clearance face in both concave and flatshapes are introduced.

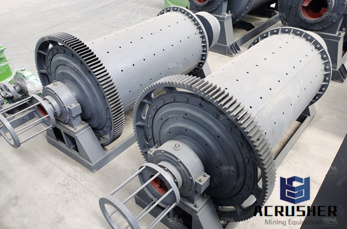

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

From the operation mechanism of the ball mill with double inlets and outlets, this paper gives a research work to the simulation of the ball mill with double inlets and outlets, and proposes a corresponding mathematical model of the six controlled with six control variables of the ball mill with double inlets and outlets, and simulates with Matlab using the operation data of a power plant.

From the operation mechanism of the ball mill with double inlets and outlets, this paper gives a research work to the simulation of the ball mill with doub Research of Mathematical Model of the Ball Mill with Double Inlets and Outlets IEEE Conference Publication

A. Modelling Study of Tube Ball Mills 1. Initial Model of the TubeBall Mill The mathematical model of the TubeBall mill was developed based on fluid mechanics; principles electrical engineering, thermodynamics and aerodynamics Wt K A t K A t cfP fP () ()=⋅ + ⋅ 11 2 2 (1) As the total mass of coal fed into the mill per hour is given in

The mathematical model is transparent with the respect to engineering process as all the parameters of the model have their specified physics meaning. The mathematical model has been implemented online and is used for condition monitoring. II. DEVELOPMENT OF A TUBEBALL MILL MATHEMATICAL MODEL A tubeball mill structure is illustrated in Figure 1.

In this work, a mathematical model is built using only experimental data of a four high tandem cold rolling mill, a set of input variables involving characteristics of the process. The performance of the model is determined by residual analysis considering new data.

[25,26] The ball mill with double inlets and outlets is a complicated object with multivariable coupling, nonlinear and timedelay, and the mathematical mode is difficult to be set up due to its ...

A mathematical model of heat transfer in a directlyfired rotary kiln is developed and used to examine the effects of operating and design parameters on burden temperature. The model includes a mean beam length radiation model and axial zoning. Conductive and convective heat transfer are also included. Radiation between

Mathematical model for ball mill mathematical model of a ball mill mathematical model grinding machining process cutting experiment of ball end mills and the calculation for a ball end mill a ball end mill parametric design system is built by development technology with catia 3d.

ppt on mathematical model for prediction of cone crusher. ppt on mathematical model for prediction of cone crusher description of the dem with fast brekage model ResearchGate IMPROVED DEM MODEL FOR PREDICTING CONE CRUSHERS'' understanding the physical phenomena, and then expressing that by mathematical means.

A new mathematical model for grinding the ball part of a ball end mill is proposed. The complete process for manufacturing a ball end mill is formulated, including processes such as modeling the rake and clearance faces. The helical flute surface of the ball end mill is analytically calculated and verified by means of simulation and experiment.

Mar 01, 1986· Powder Technology, 47 (1986) 87 96 Mathematical Model of Ball Wear in Grinding Mills 1. ZeroOrder Wear Rate J. MENACHO Mining and Metallurgical Research Center, CIMM, Casilla 170, Correo 10, Santiago (Chile) and F. CONCHA Department of Metallurgical Engineering, University of Concepcion, Casilla 53C, Concepcion (Chile) (Received November 6, 1985) 87 SUMMARY Using a .

The experiments of various authors confirm the laws of the process of milling in a drumtype ball mill, as derived from an analysis of the authors'' proposed model. 2. The optimum control law found by analysis of the model is very similar to the wellknown "Mekhanobr" principle.

Geometallurgy relates to the practice of combining geology or geostatistics with metallurgy, or, more specifically, extractive metallurgy, to create a spatially or geologically based predictive model for mineral processing plants. It is used in the hard rock mining industry for risk management and mitigation during mineral processing plant design. It is also used, to a lesser extent, for ...

MATHEMATICAL MODELING A. BALL AND BEAM SYSTEM: The ball and beam module consists of a steel rod in parallel with a nickelchromium wire wound resistor forming the track on which the metal ball is free to roll. The position of the ball is obtained by measuring the voltage at the steel rod. When the

Mathematical Model Of A Ball Mill Customer Case. Coal Grinding; Coal contains in the ducts and the dedusting installation after the mill. 3) In airswept mills, of both the ball and Mathematical_model .

A mathematical model of coal mills is developed using computational intelligent algorithms for prediction of potential mill faults. The PhD research project is to examine if it is possible to minimize the mill faults and fires in the Tube Ball mill operation by using a model based approach.

Mathematical model of ball wear in grinding mills I. Zeroorder wear rate Using a population balance approach, a general mathematical model is developed for the ball wear in rotary grinding mills. The firstorder partial differential equation obtained is solved, using a zeroorder kinetic as constitutive equation for the ball wear, obtaining ...

A mathematical model is a description of a system using mathematical concepts and process of developing a mathematical model is termed mathematical models are used in the natural sciences (such as physics, biology, earth science, chemistry) and engineering disciplines (such as computer science, electrical engineering), as well as in the social sciences (such ...

Experimental results showed that the mathematical models could directly predict the internal parameters of ball mill once the external signals were obtained. The trisensor measurement method and the mathematical models proposed in this paper provided a new way and solid basis for optimization and control of ball milling.

Parameters of the model for the ball mill and hydrocyclone are chosen according to the ... This book is intended as a compact introduction to the mathematical treatment of the unit operation of ...

The models used are the perfect mixing model for ball mills and the efficiency curve model for separators. Ball mill model for steady state operations includes two sets of model parameters, i. e. the breakage function (aij) and a combined breakage/discharge rate (ri/di) function. . . 0 1 − +∑ − = = i i i i i j ij i i i i d p p a r d p f r ...

WhatsApp)

WhatsApp)