Vertical Roller Mill for Cement Market 2020 Global Industry

Press release GLOBAL INFO RESEARCH Vertical Roller Mill for Cement Market 2020 Global Industry Analysis, Key Players, Segmentation, Services, Solutions, Trends and Forecast By 2025 ...

WhatsApp)

WhatsApp)

Press release GLOBAL INFO RESEARCH Vertical Roller Mill for Cement Market 2020 Global Industry Analysis, Key Players, Segmentation, Services, Solutions, Trends and Forecast By 2025 ...

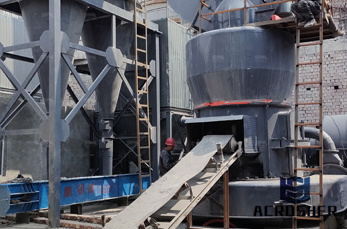

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of .

May 18, 2017· KHD Roller Presses are based on highend process technology and provide a reliable solution for grinding cement, slag, clinker, raw material, and for .

Roller Press Grinding Theory In Cement. Process of roller press grinding ball mill in our country, the promotion and use of vertical grinding mill seems a bit to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity gauguin is.

The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing. Improve production while reducing energy consumption. The flexible Hydraulic Roller Press is suitable for both upgrades and new installations.

The finished product cement from this system has all been further ground in the ball mill, so it has wide particle size distribution and stable performance. However, due to the fact that the materials rolled by the roller press are not sorted, a large amount of fine powder is returned to the roller press. If the return proportion is more than ...

the cement and minerals industry. Always up to expectations. The KHD Humboldt Wedag Roller Press is available in ten standard sizes ranging in grinding force from 2 to 32 meganewtons. The specific grinding pressure is kept below N/mm 2 in order to limit the stress on the rollers (grinding pressure = grinding force/roll diameter/roll width ...

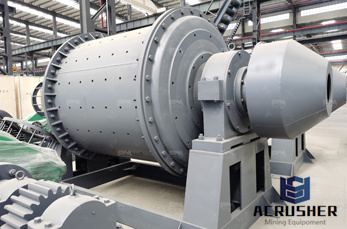

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

A roller press is installed in front of grinding installations to cut down energy consumption in the grinding unit. Installation of a roller press before rolling mill or cement mill in cement plants is now becoming a common feature. In a roller press, clinker material is subjected to extreme pressure between opposing rollers for a short time ...

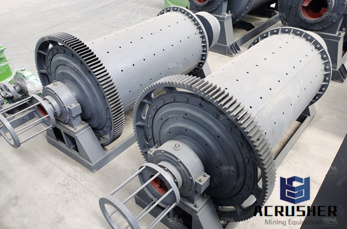

Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two.

ROLLER PRESS. HIGH PRESSURE GRINDING ROLLS MAIN FEATURES First application 1984 Today worldwide more than 600 mills in operation. Throughput rates up to 1300 t/h. Grinding force from 2 to 20 Mega Newton. Efficiency to times higher than ball mill to times higher than vertical roller mill Cement finish grinding limited by PSD.

type of roller pressing mills in cement. press cement mills. Type Of Roller Pressing Mills In Cement. Modern processing techniques to minimize cost in cement vertical roller mill vrm the power used for the actual grinding process while grinding raw materials depends mainly on the hardness of raw materials and the type of mill used ie ball mill or vertical roller mill typically the motor of the ...

Highpressure rolling mills and rotary kilns are particularly demanding applications that call for maximum performance and reliability from the drive systems. The grinding process must be guaranteed energyefficient and reliable at the same time. Our planetary gear units have been used as drives in roller presses and rolling mills for decades.

Aug 22, 2020· Roller Press + Ball mill circuit for Cement production | Higher grinding plant process availability. Acceptability of Roller press combination with Ball mill...

Roller Press + Ball mill circuit for Cement production | Higher grinding plant process availability. Acceptability of Roller press combination with Ball mill...

cement manufacturing equipment mass balance. cement mill with a roller press mass balance. NEWSLETTER European Cement Research Academy. May 5, 2011 Cement will remain the key material to satisfy ECRA''s programme begins with a conference on new cements and in a good CO2 balance. is the vertical roller mill (VRM) (Fig. 1). similar to those of the roller press.

Roller press, new energysaving grinding equipment developed in middle 1980s, can replace the ball mill competently or in partial. Roller press is characterized by low power consumption and lower noise for reforming old factories Hydraulic Roller Press at site Construction of Hydraulic Roller Press

Roller Press In Cement Mill Cement mill wikipedia a cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Comparison Erp V S Roller Press Ball Mill Merits Dem. Comparison between ball mill and roller pressparison erp v s roller press ball mill merits dem comparison erp v s roller press ball mill merits dem about cement mill formulas crushed stone supply and pr abirami cotton mills p150 hp motor stone crusher ball mill for dry grinding 1200 comparison erp v s roller press ball chat.

China Roller Press Cement Mill Grinding Unit China ...Rolling Mill, Cement Grinding Mill, Cement Roller Press manufacturer / supplier in China, offering Roller Press Cement Mill Grinding Unit, 5000 Tons Per Day Clinker Making Line and Cement Producing Plant, 5000 Tons Per Day Modern Dry Cement Clinker Rotary Kiln Production Line and so on.

The ball mill process scheme of cement ball mill and roller press is a mature process system at present which can meet the basic needs of grinding process to the greatest extent after the combined cement grinding system of 48m 95m ball mill and roller press is put into production the output of the system is low and the energy consumption.

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the ...

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

This roller press can improve the grinding capacity by 50 compared to ball mill systems and reduce the power consumption of the grinding system by 3040%, and 2030% that of finished cement. The squeezed materials is easy to grind and fine material accounts for 3030% and material smaller than 20 mm accounts for 6585%.

WhatsApp)

WhatsApp)