Harvey Tool Carbide Keyseat Cutters Square

Over 850 Harvey Tool Square Miniature Keyseat Cutters stocked in cutter diameters ranging from 1/16" up to 5/8" with 4,6,8,10,12 flute options! Same Day Shipping!

WhatsApp)

WhatsApp)

Over 850 Harvey Tool Square Miniature Keyseat Cutters stocked in cutter diameters ranging from 1/16" up to 5/8" with 4,6,8,10,12 flute options! Same Day Shipping!

PQN04 series planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume hightech material production and even colloidal grinding. They are the ideal wet/dry milling tools for acquiring research samples with .

Beltdrive Ball Mill Market Insights 2019, Global and ... Beltdrive Ball Mill Market Insights 2019, Global and Chinese Analysis and Forecast to 2024 is a market research report available at US 3000 for a Single User PDF License from RnR Market Research . Global Ball Mill Market Research Report 2019 : MIKRONS ...

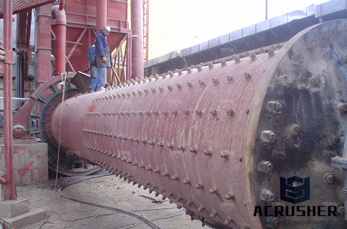

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Planetary ball mill is a most frequently used system for mechanical alloying since only a very small amount of powder is required. Therefore, the system is particularly suitable for research purpose in the laboratory. The ball mill system consists of .

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work . The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials. Depending on the desired final fineness, the .

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

Modeling and simulation of continuous open circuit dry grinding in a pilotscale ball mill using Austin''s and Nomura''s models. Powder Technology 2018, 340, 7787. DOI: / François K. Mulenga. Sensitivity analysis of Austin''s scaleup model for tumbling ball mills — Part 1. Effects of batch grinding parameters.

market research for ball mills; Ball Mills Market Transparency Market Research. The Ball Mills Market is segmented based on types of mills viz., drum ball mill, jetmill, beadmill, horizontal rotary ball mill and vibration ball mill.

Ball milling is suggested as a novel method for enhancing filler dispersion in different matrices that is environmentally and economically sustainable [85]. It is a solidstate mixing of powders, usually performed with ball mills, which enables intimate mixing of .

Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals.

The Ball Mills Market is segmented based on types of mills viz., drum ball mill, jetmill, beadmill, horizontal rotary ball mill and vibration ball mill. Key driver of Ball milling Market compared to other grinding systems is its low cost of installation and high energyefficiency.

Further, ball mills are divided into dry type ball mill and wet type lattice ball, according to different raw materials and discharging methods. These are especially used in mining industry to grind various ores and rocks in metal and nonmetal mines, either wet or dry as per the requirements. Ball Mills Market: Trends and Drivers

Several types of ball mill exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

Apr 07, 2015· Ball Mills are systems developed for refining particles or desagglomeration of aggregated species. This capability makes ball mills a useful tool for up and downstream processes in a range of applications in the pharmacy, food technology, chemical industry etc. The specific surface area of ...

Orbis Machinery, LLC is an independent, ownermanaged design, engineering and manufacturing company of process equipment. With nearly 60 years of combined process and engineering knowledge, Orbis Machinery specializes in double arm mixers, tumble and ribbon blenders, ball mills and rolling mill solutions for the process industry.

Market Research Report on Wet ball mill Market Insights 2019, Global and Chinese Analysis and Forecast to 2024 (Pages 137), Market Share, Market Size, Market Analysis, CAGR Forecasts, Top Manufacturers and Regions USA, UK, Europe, APAC, Middle East, Japan and Africa.

II314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of Cape Town, Rondebosch, 7700, South Africa ...

However, rod mills, like crushers, must be operated under controlled conditions to obtain maximum efficiency and are more difficult to operate than ball mills. Thus, the ultimate choice between a rod mill or ball mill for the primary grind may depend on the operator''s or designer''s experience as much as the metallurgist''s research.

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work . The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials. Depending on the desired final fineness, the grinding can be ...

Mar 18, 2018· Ball Mill The rotation of the Ball mill causes the charge consisting of grinding media (steel balls) and feed material to be lifted due to centrifugal forces and friction between the media and the lining. The height to which the charge is lifted d...

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

RETSCH is the world''s leading manufacturer of laboratory mills jaw crushers, sieve shakers sieves as well as sample preparation equipment.

The 21 Liter (5 gallon) 911METALLURGY 911MPE21BM dual function Laboratory Rod Mill / Ball Mill is designed to meet the industrial requirements to grind coal, cement and a wide variety of ores. The dual duty Laboratory Grinding Mill consists of a gear motor mounted on a high precision solid steel underframe complete with outlet funnel and a set of separation screens plus sample collector.

WhatsApp)

WhatsApp)