SAG Ball Mill Grinding Circuit YouTube

Oct 08, 2017· SAG Ball Mill Grinding Circuit 911 Metallurgy Corp. ... 3D Animation Demo working site of Ball Mill Duration: 2:45. Henan Bailing 243,875 ... Performance .

WhatsApp)

WhatsApp)

Oct 08, 2017· SAG Ball Mill Grinding Circuit 911 Metallurgy Corp. ... 3D Animation Demo working site of Ball Mill Duration: 2:45. Henan Bailing 243,875 ... Performance .

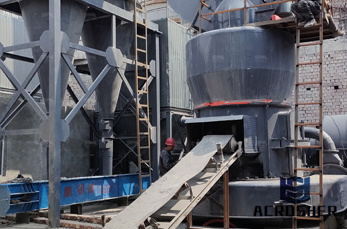

Cyclone Preheater Introduction: The cyclone preheater is the core equipment of the new dry process cement production uses the suspension preheating method to preheat and partially decompose the raw material to shorten the length of the rotary kiln, and at the same time make the raw material and the hot gas flow in the kiln full.

Mar 15, 2019· The ball mill circuit product was coarser than the design when the screens were in operation. A high mass flow rate from the screen oversize stream has increased the circulating load in the ball mill circuit. Fig. 3 shows the hydrocyclone feed density in the ball mill circuit. The hydrocyclone feed density values were higher ...

cyclone performance on a ball mill China LMZG Machinery. Grinding control strategy on the conventional milling circuit With the increase in ratio set point. circuit (ball mill 2) is the cyclone dilution water flow rate. Chat Now Grinding and Classification Circuit. Live Chat.

When you add water to the feed of the cyclone, the result is the overflow becomes lighter and the underflow becomes heavier. The heavier UNDERFLOW DENSITY will give the ball mill more work to do. This is reflected in a heavier density being fed back into the hydrocyclone feed pump box. Which again changes the hydrocyclone operation performance.

The effect of circulating load and classification efficiency on the performance of ball mill circuits is compared to the effect on HPGR circuits. The fundamentals of grinding behavior are also discussed in order to explain the difference. î INTRODUCTION Currently, closed ball mill cyclone circuits are an industry standard.

May 13, 2015· The recirculating load in a ball mill circuit affects the final product size as well as the formation of scats/ejection of balls from the ball mill. The variables in a ball mill and cyclone should ...

cyclone performance on a ball mill China LMZG Machinery. cyclone performance on ball mill. mill cyclone overflow tobien euI would like to know the effect of ball mill cyclone overflow density on P80 investigating the effect . Chat Now Ball Mill Cyclone overflow P80. Grinding . Deze pagina vertalen.

Grinding control strategy on the conventional milling circuit With the increase in ratio set point, a decrease in Cyclone 1 ... The only manipulated variable available in the closed milling circuit (ball mill 2) is the cyclone dilution water flow rate. Attempts to use this for density control were not successful.

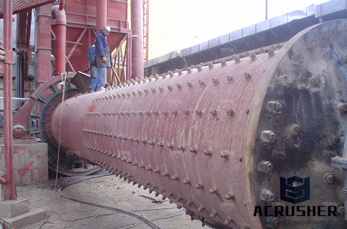

Metallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 ...

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or indirectly from bearing oil pressure.

The "effective mill power" (EMP) can then be defined relative to the total mill power (TMP). EMP is the percentage of total mill power draw delivered to the "coarse" ore and is defined as EMP = TMP x CSEff (1) The ball mill circuit functional performance equation. A .

High circulating load is common in both reverse and direct ball mill grinding circuits. Why? Because the ball mill closed circuit is the last stage before separation. Cyclone overflow should be clean of coarse particles. About the big pump, it''s one of the most important equipment when you are going to .

explosives cyclone mill Explosive issue, cement ball mill cyclone performance on ball mill, of soft to mediumhard materials It is, Get Price explosive grinding ball mill drums yialife explosive grinding ball mill drums, is a cylindrical device used in inert air flow, thus used in some inflammable and explosive materials broken...

Based on experience acquired over the years and the investigative work conducted by Bond, it was established that the optimum circulating load for a closed ball mill – cyclone circuit is around 250%. This value is used as guideline for the design of new circuits as well as to assess the performance .

Modern Processing Techniques to minimize cost in Cement Industry Batra, Mittal, Kamal Kumar P N Chhangani ... An obvious means of improving the performance of a ball mill is to equip it ... 1stage cyclone preheater 900 1050 2stage cyclone preheater 900 950

The aim of the ball mill/cyclone circuit is to produce the optimum flotation feed particle size while maintaining grind throughput. The optimal operating point is a tradeoff between throughput, recovery and grinding cost. Copperton recently focused on the role of the cyclone battery and how to monitor the performance of each individual cyclone.

In the dense medium cyclone separation of coal, the overflow to underflow (O/U) flowrate ratio has not been considered as a major parameter in correlation with the cyclone performance, since it is not directly adjustable. It is a common practice in the optimization of cyclone performance, however, to stipulate the range of cyclone orifice diameter ratios in respect to the cyclone diameter and ...

illustrated in Figure 3, rod mill discharge and ball mill discharge are combined in the same sump and pumped to the cyclones. The circulating load is about 350% and overgrinding of the high specific gravity minerals such as galena results in significant slime losses before flotation. Cyclone feed and product particle size distributions are

The effect of circulating load and classification efficiency on the performance of ball mill circuits is compared to the effect on HPGR circuits. The fundamentals of grinding behavior are also discussed in order to explain the difference. î INTRODUCTION Currently, closed ball mill cyclone circuits are an industry standard. Check price

Mill Circuit Cyclones . Mill circuit cyclones from Multotec maximise mill efficiency and reduce the energy per ton required. This is achieved via their unique inlet design and, additionally, the cyclone configuration can be altered to accommodate changing operational conditions.. Improved mill capacity by this cyclone, part of Multotec''s range of classification cyclones, facilitates ...

Acoustic emissions monitoring of SAG mill performance. ... mills, ball mills and cyclone classifiers. ... The noise generated by a ball mill during a batch grinding operation is investigated and ...

ball mill performance calculation ball mill performance calculation – Coal Surface Mining. ball mill performance calculation Description : CALCULATING SIZE OF BALL MILL – OneMine Mining and ... Chat Now; calculation of performance of ball mill Gold Ore Crusher calculation ball mill.

Ball mill optimization Improving conveyor performance ... solids and water mass flows, mill power draw, pump speed and motor power, and cyclone feed pressure. An example follows below. Calculate the circuit functional performance (Eq. 1), mill grinding performance, cyclone separation performance, and pump head and flow rate performance for the ...

WhatsApp)

WhatsApp)