Measuring Coal Pipe Flow

Combustion tuning of a pulverized coal boiler begins with balancing the air and fuel flows in the coal pipes from the pulverizers to the burners. Note that each of the coal pipes is a different ...

WhatsApp)

WhatsApp)

Combustion tuning of a pulverized coal boiler begins with balancing the air and fuel flows in the coal pipes from the pulverizers to the burners. Note that each of the coal pipes is a different ...

Sep 16, 2010· mason coal burner wrote:they make 6" and 8" thimbles . I would get a redooser to go from 7"8" . get 8" thimble and 8" x 8" flue . inside of thimble measures 8" outside is about " some may vary . pipe at stove goes inside stove not outside .

Online coal and primary air flow measuring devices can be helpful to more precisely balance pipetopipe coal and air flows. ... burner retrofits include a mill evaluation and test program to ...

Ensuring the correct/optimal raw coal size and its supply to the mill 16 ... Optimising fuel flow in pulverised coal and biomassfired boilers 10 ... high coal flow to burners can create carbonrich zones with a reducing atmosphere that leads to increased slagging and carbon monoxide (CO) emissions. ...

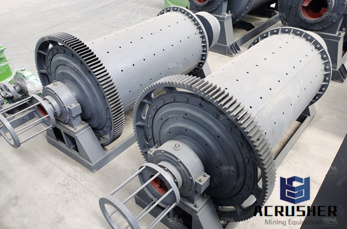

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it ... and out the exhaust pipe directly to the burner. Coal that has not been pulverized into fine enough particles cannot be blown ... important to size the system for the oil viscosity at the coldest ...

Individual pipetopipe velocities can be measured with the use of an isokinetic coal sampler, and the data collected is important in identifying burner issues, blockages, coal ropes, slow ...

pulverized coal (fuel) carried by air in pipenetworks to feed the boiler furnaces of a powerstation. The pipenetwork considered consists of four 457mmdiameter mill pipes which take the pulverised coal of nominal size 75micron from a coalpulverising mill, to a boiler furnace, with 2 pipes going to its front, and 2 to its back side.

The measurements and particulate sampling were repeated for eight PC pipes located at two different elevations. Two separate mills, referred to as Mill 20 and Mill 40 in this paper, supply pulverized coal to the four PC pipes (and burners) for each elevation.

17_Coal [Mills]. 3. This coal is conveyed by combustion air to the coal burners to burn in the furnace . can be ground in a test mill to specified fineness . (air velocity in . air at mill inlet, Ti. Fuel . Hot air is a product of preheated air and cold air. Read More; Dust collector Wikipedia

Mar 01, 2011· Scottsman wrote:Calling on the collective widsom of the forum...I have a big coal/wood stove with an 8" flue outlet that I want to install to a 6" diameter Duravent was thinking of using this 8" stove pipe I bought with it and using an 8" to 6" reducer right .

Milling Plant Mill sizes • The nominal diameter of the ring or racer or wheel is the prime dimension in a mill. • In about six to eight ring sizes of —1750 to 3500 mm (—70 to 140 in.), a range of about 20100 tph of coal grinding can meet large boiler requirements.

The dimensions you stated for your combustion chamber and heat riser are ok. you have 6"x4" (cross sectional area of 24 sq inches) feeding 5"x5" (25 sq inches) but you want to exhaust the system to 3" pipe ( x x = 7 sq inches) yikes! This absolutely will not fire as intended. This stove will require 6" diameter flue pipe in my opinion.

proportional to available grinding force. This implies, for example, that only six (6) or seven (7) mills of the same physical size are required today for a boiler that previously needed eight (8) mills to supply the same coal flow. This significantly reduces the initial capital investment for mills and associated burners and coal piping systems. 6

if any running Coal Mill pipe temperature goes low, below 60 C it will flash an alarm called "Any coal mill pipe temperature low". Thus we were able to execute the project and established automation for remote monitoring and measurement of coal pipe temperature of coal mill of PF boiler. Fig. 4.

through the burner lines. Keep in mind that coal is about a thousand times denser than air and is a solid. The smaller the particles, the more the solid fuel parMeasuring Coal Pipe Flow Coal pipe flows can only be balanced and optimized when they are measured. Until you have confidence in your coal flow measurements, tuning the pul

LABORATORY DEVELOPMENT LEADING TO IMPROVED METHODS OF BALANCING COAL PIPE COAL FLOWS In a pulverized coal boiler, coal and primary air flow from the pulverizers to the burners through an array of coal pipes. For proper operation of the boiler, all the pipes connected to a pulverizer should ... can occur in large diameter coal pipes at conveying ...

" Mini Glass OIl Burner Bubbler colorweight 55g14mm jointsoil burner pipe attac.. . Add to Cart. Add to Wish List. Compare this Product. 4" Glass Oil Burner Combo. 4" Glass Oil Burner Combo setinclude one lighter and 4 inch Oil burner and Pouch case assorted color.. ...

Nov 27, 2006· I have a spec sheet of some type on the OM80 Wood/Coal stove I will upload to the wiki and post the URL here. Here is basic spec it was UL approved. I have also started an old mill topic in the Wiki and have this and also another old mill spec sheet there. As far as the 8" flue size, the reason for that is the large door opening.

Orifices are often required in pulverised fuel pipes to offset differences in total pipe length and balance pressure between the fuel pipes on each mill. The Burner Isolators are designed so that the housing will also accommodate an orifice plate.

Seamless steel tubes and pipes are hot manufactured using the plug millrolling process, mandrel millrolling process, extrusion process, and push bench process. The plug millrolling process is used to manufacture mediumdiameter carbon steel tubes and lowalloy steel tubes, and the mandrel millrolling process is used to manu

This regulation, by sweeping pulverized fuel from the mill, is very fast; comparable with oil firing response, but needs the coal level to be maintained in the mill. A control circuit monitors the coal level in the mill, and controls the speed of the raw coal feeder to maintain it.

Mill, coal pipe, (inlet coal particle size 0 to 8 mm) More Info coal mill and power plant Virtual Tour of the MSU Power Plant, Notice the inlet chute where the to crush the incoming coal to the optimum size for coal mill in thermal power plant.

Coal is pulverized in the coal mill to a very fine particle size. The coal and primary air are then introduced to the coal nozzle. The coal and primary air are then introduced to the coal nozzle. Swirled air, coupled with the burner throat''s flowshaping contour, enables recirculation patterns that extend into the .

In a typical coal mill, primary air (PA) is used to both dry the coal and transport it to the burner(s). Figure 1 depicts a twopipe coal milling system showing the PA that is used to transport ...

WhatsApp)

WhatsApp)