(PDF) Processing of Magnetite Iron Ores–Comparing Grinding ...

In this work, the purpose was to study the impact of variations in feed ore properties on the performance of a primary autogenous grinding circuit by ore characterisation and simulation.

WhatsApp)

WhatsApp)

In this work, the purpose was to study the impact of variations in feed ore properties on the performance of a primary autogenous grinding circuit by ore characterisation and simulation.

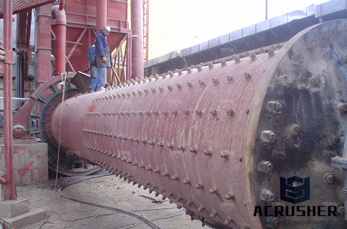

Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or varies, depending upon the type of ore and the amount of reduction required. In addition, some of the older properties continue with methods that perhaps are not considered the best in light of recent improvements but that cannot be ...

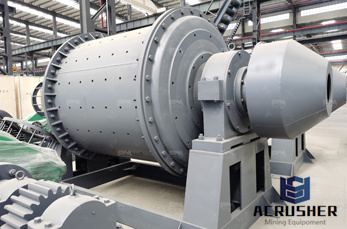

Grinding mill: The grinding mill is a key equipment to grind the crushed materials, and the grinding mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc, and the grinding mill can grind various ores and other materials with dry type ...

Blaine Index Iron Ore ContreTempsBe. Blaine index iron ore grinding mill iron occur in femineral ores contains impurities of phosphorus, sulphur and highalkali as well as impregnations of waste produce a metallurgy is blaine number for iron ore.

grinding process in iron ore. Grinding In Iron Ore Process Iron ore grinding mill Grinding plants for Iron Ore Iron ore is an important industrial source is an iron oxide ore a mineral aggregate containing iron elements or iron compounds that can be economically utilized and there are many types of iron ore

Jan 12, 2020· The iron content of the ore needs to be increased and gangue, which is native rock and minerals of lesser value within the ore itself, must be separated out. Methods such as screening, crushing, and grinding of iron ore are often used in various ways to purify it, along with several stages of magnetic separation.

Iron Ore Processing description: Iron ore beneficiation process should be as efficient, simple to the extent possible in the most appropriate process to achieve the best effects. In the concentrator, the crushing and grinding operations of equipment investment, production costs, power consumption and steel consumption is often the largest ...

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

It''s all about volume. In the iron ore industry, you want the largest possible throughput of iron ore through your processing equipment. That''s why you need the most reliable and proven equipment that never lets you down, even though it handles large tonnages every day of the year.

Introduce of iron ore grinding plant/iron ore powder processing plant: The iron ore grinding plant/iron ore powder processing plant mainly consist of hammer crusher, main unit, Frequency conversion classifier, powder collector, pulse dust cleaner,high pressure positive blower, air compressor, muffler, electrical apparatus control system, soundproof room, crusher, bucket elevator, storage ...

screens have been used in iron ore since the 1950''s processing all types of iron ore. From removing fine impurities in Direct Shipping Ore sinter products to scalping relatively coarse (+53 to 75 µm) middlings and size control in pellet concentrates.

Ren Recommends: Also like Silver, Gold Ore tends to be more valuable as ore than as a bar, though not as much. It''s also used to speed Mining leveling, but it''s not as important in this case. Iron becomes Green at 175 the same level where Mithril becomes available.

Iron ore beneficiation equipment. SBM is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant. The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, SCM Super ...

MB5X Pendulum Suspension Grinding Mill is new mature and advanced equipment. This machine adopts automatic thinoil lubricating system. iron ore crusher,mining mill and grinding, stone crusher proffesional separator barite flotation cell machinery; circuit diagram of car crusher and their explanation ...

grinding of iron ore Newest Crusher, Grinding Mill Types iron ore mining equipment,iron ore grinding mill sale in China . Caiman Mining equipment manufacturers is focused on delivering projects and services that make .

Iron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of iron ore. Among them, the iron smelting products mainly include Magnetite, siderite, and hematite and so on.

Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil. Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015.

Apr 10, 2019· In today''s video, I figure out a workaround for all that rock you have to dig out of the ground to find the Iron Ore... Also a little bit closer to leveling up, and getting another skill, if I don ...

Thousand Needles – Iron Ore farming. Farming in the Thousand Needles is more practical for the Horde, since it can be difficult to reach for Alliance players. If you are farming here, I recommend going into the caves, since they tend to have more Ore.

iron ore grinding mill loofamsterdamnl. Minerals Processing Equipment iron ore grinding mill,Grinding Minerals design and manufacture a comprehensive line of grinding mills and entire grinding systems for mining,, for modern ore processing plants with cell sizes from, iron ore concentration plant with a pelletizing systemTata Steel installs record size iron ore drying and grinding ...

Increasing iron ore demand, coupled with the depletion of highgrade hematite ores in the United States, after World War II led to development of lowergrade iron ore sources, principally the utilization of magnetite and taconite. Ironore mining methods vary by the type of ore being mined.

Leadzinc ore crushing processing. Leadzinc ore crushing processing Lead and zinc ore is the metalrich mineral elements such as lead and zinc, blue gray, hardness, it is the most soft metals, lead is one of the earlier extracted i.

This Iron Ore farming guide will list the places where you can get the most Iron. It''s recommended to have Mining skill 100 before you start farming Iron Ore, because you will get more ores. Iron Ore Feralas. You will find Iron anywhere you go in Feralas, it''s the best place to mine Iron.

This Ghost Iron Ore farming guide will show you the best places for mining Ghost Iron Ore. There are two types of Ghost Iron Deposit, one of them is the normal Ghost Iron Deposit and there is also Rich Ghost Iron Deposit. The only difference is that you get more ore from mining Rich Ghost Iron Deposit.

WhatsApp)

WhatsApp)